Ammonium nitrate (AN) is one of the most widely used materials in the mining industry for blasting and excavation. Known for its cost-effectiveness, high energy output, and stability, ammonium nitrate is essential in producing powerful mining explosives. When combined with other substances, ammonium nitrate becomes a potent explosive suitable for various applications, including rock blasting, quarrying, and large-scale excavation. This article explores how ammonium nitrate is used in mining explosives, its benefits, and the safety measures required when handling this powerful material.

1. What is Ammonium Nitrate?

Ammonium nitrate (NH₄NO₃) is a white, crystalline chemical compound commonly used in fertilizers and explosives. It has a high nitrogen content, making it valuable for agricultural use as a fertilizer. However, its oxygen-rich composition also makes it an ideal oxidizing agent in explosives. By providing oxygen to fuel materials, ammonium nitrate supports a rapid combustion reaction, making it suitable for mining applications.

2. Ammonium Nitrate in Mining Explosives

Ammonium nitrate is rarely used as a standalone explosive in mining. Instead, it is typically combined with fuel oil to create ANFO (Ammonium Nitrate Fuel Oil), one of the most widely used blasting agents in mining operations. ANFO is a mixture of approximately 94% ammonium nitrate and 6% fuel oil, creating a powerful explosive that is both efficient and cost-effective.

Types of Explosives Involving Ammonium Nitrate

ANFO (Ammonium Nitrate Fuel Oil): A stable, easy-to-use explosive made from ammonium nitrate and fuel oil. It is ideal for dry conditions and accounts for the majority of explosives used in surface mining.

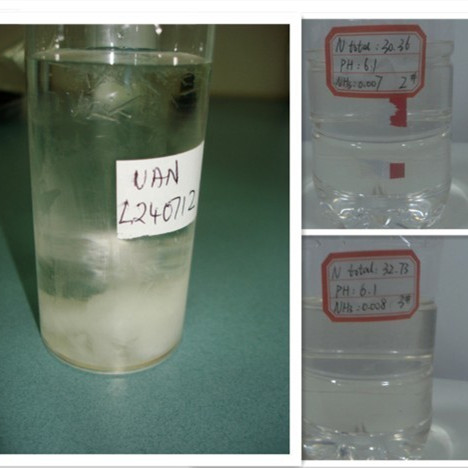

Emulsion Explosives: These are water-resistant and contain a mixture of ammonium nitrate, water, fuel, and emulsifying agents. Emulsion explosives are used in wet or underwater conditions where ANFO would be ineffective.

Slurry Explosives: A thickened liquid explosive that includes ammonium nitrate, water, and other chemicals. Slurries are less common than emulsions but are still used in some mining environments.

Each type of ammonium nitrate-based explosive offers distinct advantages and is chosen based on the specific needs of the mining operation.

840708.webp)

Size Specifications Table

| Parameter | Specification | Description |

|---|---|---|

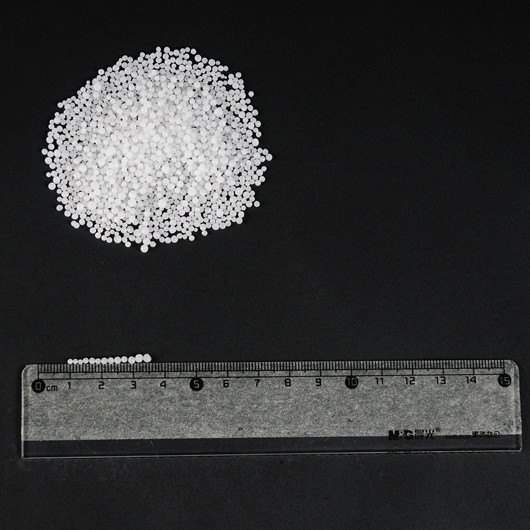

| Particle Size | Prilled (1.0-2.5 mm) | Prilled ammonium nitrate is commonly used for ANFO as it allows better absorption of fuel oil. |

| Bulk Density | 0.72 - 0.85 g/cm³ | Bulk density of the prills affects the energy and oxygen balance in ANFO formulations. |

| Porosity | High Porosity (15-20%) | High porosity allows better absorption of fuel oil, making the mixture more effective in blasting. |

| Shape | Spherical Prills or Granules | The prilled form is preferred for mining as it’s easy to handle and mix with fuel oil. |

| Packaging | 25 kg, 50 kg bags, or bulk in tonnage | Packaged in moisture-resistant bags or in bulk for easy transportation and storage. |

Technical Specifications Table

| Parameter | Specification | Description |

|---|---|---|

| Purity | ≥ 99.5% | High purity ensures consistent performance and reactivity. |

| Nitrogen Content | 34% - 35% | Essential for explosive power, high nitrogen content makes ammonium nitrate a strong oxidizer. |

| Moisture Content | ≤ 0.2% | Low moisture content is critical to prevent clumping and ensure effectiveness. |

| Density | 1.725 g/cm³ (solid) | High density helps with compact storage and ensures a stable product. |

| Oxygen Balance | +20% | Positive oxygen balance aids in complete combustion of fuel oil, making ANFO a powerful explosive. |

| Melting Point | 169.6°C | Ammonium nitrate decomposes at high temperatures, so it is stable under most storage conditions. |

| Decomposition Temperature | 210°C - 240°C | Thermal decomposition should be avoided in storage; requires temperature control. |

| Heat of Explosion | 4.1 MJ/kg | High energy release during explosion, providing strong blasting power. |

| Compatibility with Fuel Oil | Excellent | Ammonium nitrate readily absorbs fuel oil, forming a stable and effective explosive mix (ANFO). |

| Sensitivity to Shock/Impact | Low | Ammonium nitrate alone is not sensitive to shock or impact, making it safe to handle in isolation. |

| Compatibility with Other Explosive Additives | High | Can be combined with emulsifiers and other agents for various explosive formulations. |

3. Advantages of Ammonium Nitrate as a Mining Explosive

Ammonium nitrate-based explosives offer several advantages that make them suitable for mining applications:

Cost-Effectiveness: Ammonium nitrate is relatively inexpensive compared to other explosive materials, making it ideal for large-scale mining operations where cost efficiency is essential.

High Energy Output: ANFO and emulsion explosives produce a high-energy blast that is capable of breaking through dense rock formations, which is crucial in mineral extraction.

Ease of Use and Transport: Ammonium nitrate is relatively safe to handle and transport in its unblended state. It only becomes explosive when combined with fuel, allowing for safer transport and storage.

Customizable: By adjusting the ratio of ammonium nitrate to fuel or modifying the emulsion composition, mining operators can create explosives tailored to specific blasting needs.

Stability: Ammonium nitrate is stable under normal conditions, reducing the risk of accidental detonation, which is a critical factor in high-stakes mining environments.

4. Safety Considerations When Handling Ammonium Nitrate

While ammonium nitrate is stable and safe in its unprocessed form, it poses significant risks when improperly handled. Due to its potential as an explosive ingredient, strict regulations govern the handling, storage, and use of ammonium nitrate in mining operations. Here are some key safety considerations:

4.1 Storage Guidelines

Secure Facilities: Ammonium nitrate should be stored in secure, well-ventilated facilities that are far from sources of heat, open flames, and incompatible chemicals like fuels and oxidizers.

Temperature Control: High temperatures can increase the sensitivity of ammonium nitrate, so storage areas should remain cool and dry to prevent decomposition.

Separate from Fuel: Ammonium nitrate should never be stored with fuel oil or other flammable materials to prevent accidental formation of ANFO or other explosive mixtures.

4.2 Transportation Precautions

Proper Labeling and Documentation: Transportation of ammonium nitrate requires proper labeling to indicate its contents and ensure compliance with local and international regulations.

Specialized Transport Vehicles: Vehicles used to transport ammonium nitrate must be suitable for hazardous materials and equipped with firefighting equipment in case of emergency.

4.3 Mixing and Blasting Safety

Controlled Mixing: ANFO and other ammonium nitrate-based explosives should only be mixed in controlled environments, typically at the blasting site. This minimizes the risk of accidental detonation during transport.

Use of Detonators: Blasting operations should be conducted by trained professionals who are well-versed in the safe use of detonators and timing devices.

Personal Protective Equipment (PPE): Workers handling ammonium nitrate and related explosives should wear PPE, including gloves, safety glasses, and protective clothing, to minimize exposure to hazardous materials.

4.4 Compliance with Regulations

Regulatory Oversight: Government agencies impose strict regulations on the handling and use of ammonium nitrate in mining to prevent accidents and misuse. Compliance with these regulations is essential for safe operations.

Training and Certification: Only certified professionals should be allowed to handle and deploy ammonium nitrate-based explosives in mining. Regular training ensures that workers remain informed of safety procedures and emergency protocols.

5. Environmental Impact and Alternatives

The use of ammonium nitrate in mining has raised environmental concerns due to its potential impact on soil and water quality. Unexploded residues of ammonium nitrate can leach into groundwater, potentially harming local ecosystems. As a result, mining companies are increasingly exploring eco-friendly alternatives, such as:

Biodegradable Emulsion Explosives: Some emulsion formulations use biodegradable materials, reducing environmental impact while still providing effective blasting performance.

Recycling of Explosive Residues: Innovative recycling techniques allow mining companies to reduce the amount of ammonium nitrate residues left in the environment, lowering the risk of contamination.

Efforts to reduce the environmental impact of ammonium nitrate-based explosives are ongoing, as mining companies strive to balance operational efficiency with sustainability.

6. Applications in Mining

Ammonium nitrate-based explosives are versatile and can be used for a variety of applications in mining, including:

Rock Blasting: ANFO and emulsion explosives are ideal for breaking up rock formations, making it easier to access valuable minerals.

Quarrying: In quarry operations, ammonium nitrate explosives help create manageable rock sizes, facilitating transport and processing.

Underground Mining: Specialized ammonium nitrate-based explosives are used in confined underground spaces, where safety and control are paramount.

Construction and Tunneling: Outside of traditional mining, ammonium nitrate explosives are also used in construction projects to excavate tunnels and foundations in rock-heavy areas.

7. Conclusion: The Role of Ammonium Nitrate in Modern Mining

Ammonium nitrate is a fundamental component in the mining industry, offering a reliable, cost-effective, and powerful means of rock excavation. When combined with fuel oil or other agents, it becomes an explosive capable of breaking through tough rock formations, allowing for efficient mineral extraction. However, the use of ammonium nitrate requires strict adherence to safety guidelines to prevent accidents and minimize environmental impact.

The mining industry continues to innovate and improve safety practices around ammonium nitrate-based explosives, balancing operational needs with environmental responsibility. As technology advances, the development of safer, more sustainable alternatives may reduce reliance on ammonium nitrate in the future. Until then, ammonium nitrate remains a cornerstone of mining operations, providing the power and efficiency required for large-scale excavation and mineral extraction.