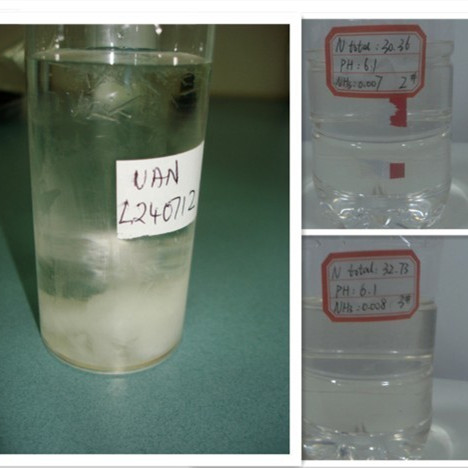

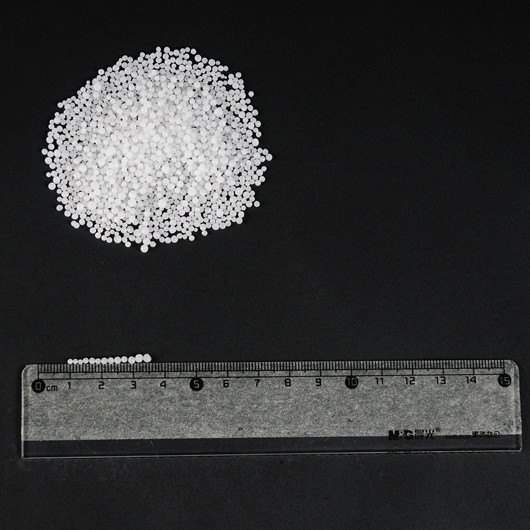

1. Chemical and Physical Properties of Calcium Nitrate

Calcium nitrate, with the chemical formula Ca(NO₃)₂, is a white, crystalline, or granular substance. It has a molecular weight of 164.1 g/mol and is commonly available in anhydrous or tetrahydrate forms. As a highly soluble salt, it dissolves readily in water, with solubility reaching 1212 g/L at 20°C (68°F). This high solubility makes it a popular choice for agricultural applications, particularly in hydroponics, where it provides both calcium and nitrogen to plants.

Thermal Properties

Calcium nitrate has a melting point of 561°C (1042°F), and when exposed to temperatures above 500°C, it begins to decompose. This decomposition releases toxic nitrogen oxides (NOx), which are harmful to both humans and the environment. In confined spaces or poorly ventilated areas, these gases can pose significant health risks. For example, inhaling nitrogen dioxide (NO₂) can cause severe respiratory irritation and long-term lung damage, with exposure limits set by OSHA at 5 ppm (parts per million).

Hygroscopic Nature and Impact on Storage

One of the most important physical characteristics of calcium nitrate is its hygroscopic nature. It easily absorbs moisture from the surrounding environment, even under normal conditions, which can lead to clumping, caking, or the formation of a slurry. This behavior is especially problematic in regions with relative humidity levels above 40%, as the product can degrade within 24–48 hours without proper packaging. The moisture uptake not only reduces the effectiveness of the fertilizer but also makes it difficult to handle and apply.

Oxidizing Properties and Hazard Classification

The United Nations has classified calcium nitrate as a Class 5.1 oxidizer (UN 1454), which means it has the potential to intensify the combustion of other materials. In practical terms, this means that storing calcium nitrate with flammable substances such as wood, paper, or oil can significantly increase the risk of fire or explosion. In several documented incidents, improper segregation of calcium nitrate from organic materials has resulted in warehouse fires, underscoring the need for strict adherence to storage protocols.

2. Safety Risks and Precautions

Handling calcium nitrate poses several risks, such as exposure to toxic fumes and chemical burns. The compound can cause skin and eye irritation if touched, and inhaling its dust may cause respiratory discomfort. OSHA's (Occupational Safety and Health Administration) permissible exposure limit (PEL) for airborne particulate matter is 15 mg/m³ for total dust and 5 mg/m³ for respirable dust.

A real-world example of hazards occurred in 2021 when a warehouse storing fertilizers, including calcium nitrate, caught fire in Gujarat, India, resulting in a chemical explosion due to poor segregation of chemicals. This incident underscores the importance of separating oxidizers from flammable substances.

Personal Protective Equipment (PPE) Recommendations:

Gloves: Nitrile or PVC gloves to prevent skin contact.

Eye Protection: Safety goggles or face shields rated to protect against chemical splashes.

Respiratory Protection: If the dust concentration exceeds 5 mg/m³, use N95 respirators or P100 masks.

3. Handling Procedures: Reducing Risk during Use

Proper handling of calcium nitrate is essential to minimize safety risks and prevent product degradation. The compound’s hygroscopic nature, oxidizing potential, and corrosive effects on certain materials demand careful procedures during both agricultural and industrial applications. Understanding the best practices for equipment selection, environmental conditions, and mixing concentrations ensures safety and maintains the product’s effectiveness.

Selection of Tools and Equipment

When transferring or mixing calcium nitrate solutions, it is important to use non-reactive materials such as stainless steel, polyethylene (PE), or polypropylene (PP) to avoid chemical reactions. Equipment made of carbon steel or iron is highly susceptible to corrosion, especially when calcium nitrate comes into contact with moisture for extended periods. Studies show that carbon steel exposed to calcium nitrate in humid environments can corrode within 48 hours, causing contamination of the solution and damage to machinery. This can lead to costly repairs or downtime, particularly in fertilizer production facilities and irrigation systems.

Temperature Control during Handling

Calcium nitrate is sensitive to heat, and elevated temperatures increase the risk of chemical decomposition, which may release toxic nitrogen oxides (NOx). Therefore, operations involving calcium nitrate, such as mixing or storage, should be conducted at temperatures below 40°C (104°F). In industrial environments, avoiding direct sunlight or heat sources near handling areas is critical to prevent product degradation or combustion risks, especially since calcium nitrate acts as an oxidizer.

Application in Agriculture

In agricultural settings, calcium nitrate is often used as a fertilizer solution to provide plants with calcium and nitrate nitrogen, both essential for crop growth. However, concentrated solutions above 10% can harm plant roots by causing osmotic stress and chemical burns. For optimal results, farmers typically use 5–10% diluted solutions. This dilution not only ensures safe application but also improves the fertilizer's absorption by plant roots and minimizes soil damage. Hydroponic growers, for instance, use precisely diluted mixtures to maintain optimal nutrient balance and pH levels, ensuring healthier crop yields.

By following these guidelines, industries and agricultural users can reduce risks, ensure operational efficiency, and prevent costly equipment failures or crop damage.

4. Storage Guidelines: Protecting Quality and Preventing Hazards

The shelf life of calcium nitrate is approximately 12–18 months if stored under proper conditions. However, improper storage can reduce its efficacy by 30–50% due to caking or moisture absorption. Below are best practices for maintaining product quality during storage:

Ideal Storage Conditions:

Temperature: Store in a cool, dry place with a temperature below 25°C (77°F).

Humidity: Maintain relative humidity below 30% to prevent the compound from clumping.

Packaging: Use airtight, moisture-resistant containers such as polyethylene-lined bags or HDPE drums.

Warehouse Requirements:

Segregation: Keep calcium nitrate away from flammable materials such as sugar, wood, oil, and sawdust.

Ventilation: Ensure proper ventilation to prevent the accumulation of nitrogen oxide fumes in case of decomposition.

Fire Safety: Equip storage areas with Class D fire extinguishers, which are suitable for oxidizer-related fires. Sprinkler systems should be avoided, as water can dissolve the nitrate and exacerbate chemical reactions.

A study by the Fertilizer Institute reported that warehouses lacking proper climate control experienced a 20–25% higher rate of product degradation due to hygroscopic behavior.

5. Regulatory Compliance and Labeling Requirements

Calcium nitrate is regulated by various international and national agencies. In the United States, the Department of Transportation (DOT) classifies it as a Class 5.1 oxidizer, requiring specific labeling and documentation during transport. Similarly, the European Union categorizes it under the REACH regulation (EC 1907/2006) as a hazardous substance.

Each package should display the GHS pictogram for oxidizers and corrosives, along with the relevant safety phrases such as “Keep away from heat” and “Wear protective gloves”. Compliance with these regulations helps prevent accidents during transport and ensures proper handling throughout the supply chain.

In 2015, a shipping company was fined $75,000 for transporting calcium nitrate without proper hazard labeling, leading to an investigation by maritime authorities.

6. Spill Management and Disposal Methods

Spills involving calcium nitrate should be handled quickly to prevent environmental contamination. Calcium nitrate runoff can contribute to eutrophication, a process where water bodies become enriched with nutrients, leading to algal blooms and oxygen depletion. In the Mississippi River Basin, nitrate fertilizers (including calcium nitrate) were found to be responsible for 50% of nitrogen pollution linked to dead zones in the Gulf of Mexico.

Steps for Managing Spills:

Contain the Spill: Use sand or other inert absorbent materials to contain the spill.

Neutralize: If necessary, neutralize with calcium carbonate to minimize reactivity.

Disposal: Collect spilled material and dispose of it according to local environmental regulations. In many jurisdictions, calcium nitrate waste must be transported to a certified hazardous waste disposal site.

7. Conclusion

Calcium nitrate is a versatile chemical with essential applications, but improper handling and storage can lead to safety risks and product degradation. Adhering to proper handling practices, such as wearing protective equipment and using non-reactive tools, reduces the risk of chemical burns and corrosion. Proper storage in cool, dry environments prevents moisture absorption, ensuring product efficacy and shelf life. Moreover, following regulations regarding labeling and spill management ensures safety throughout its lifecycle. With global demand for calcium nitrate projected to reach 6.2 million tons by 2028, proper handling and storage will become increasingly important to meet industry needs efficiently and safely.

This article outlines best practices for calcium nitrate handling and storage from multiple perspectives, combining real-world examples, regulatory requirements, and scientific data to provide a complete guide for users in agriculture, industry, and beyond. If you have other questions or need to buy calcium nitrate, please feel free to contact us and we will provide you with professional solutions.