Chemical Pure Ammonium Nitrate (CPAN) is a highly versatile chemical compound with critical applications in agriculture, mining, and explosives. Its high nitrogen content makes it an excellent fertilizer, while its properties are essential in various explosive formulations. However, its potent nature demands rigorous safety measures and proper handling to mitigate risks associated with its use. This article delves into the safety and handling protocols for CPAN, illustrating key practices with data and examples.

Properties of Chemical Pure Ammonium Nitrate

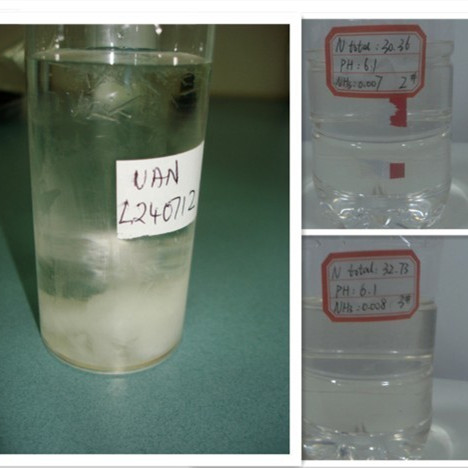

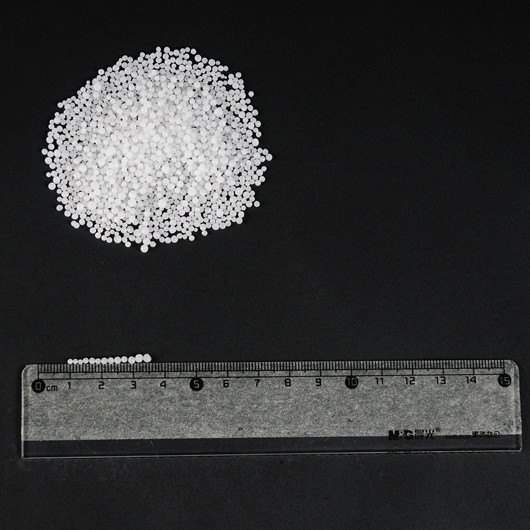

Ammonium nitrate (NH₄NO₃) is a white, crystalline solid at room temperature and is known for its wide range of industrial and agricultural uses. As a highly soluble compound, ammonium nitrate dissolves readily in water, with a solubility of approximately 1190 grams per liter at 20°C. This solubility is one of its key characteristics, making it a critical component in many applications, including fertilizers and explosives.

Chemical Pure Ammonium Nitrate (CPAN) refers specifically to ammonium nitrate that has been refined to a high degree of purity, typically containing 99.5% or more NH₄NO₃. This high purity level is crucial for ensuring the compound’s performance in sensitive industrial processes, as impurities can alter its behavior, potentially leading to less predictable outcomes. For example, in the manufacture of explosives, even small impurities can affect the stability and reactivity of the ammonium nitrate, making CPAN indispensable in such high-risk environments.

The physical and chemical properties of CPAN also make it versatile in its use, but they require careful handling. CPAN is classified as an oxidizer, which means it can accelerate the combustion of flammable materials. Under certain conditions, such as exposure to high heat or contamination with combustible substances, it can become highly explosive. Therefore, strict safety protocols are essential when storing and handling CPAN, ensuring it is kept in controlled environments away from potential ignition sources.

The high solubility and purity of CPAN make it a valuable chemical for numerous industries, but its reactive nature necessitates rigorous safety measures to prevent accidents, especially in large-scale operations.

Safety Risks and Hazards

Chemical Pure Ammonium Nitrate (CPAN) is widely used in industries ranging from agriculture to explosives production. While its applications are diverse and critical, its handling presents significant risks and hazards. The potential dangers associated with CPAN stem from its chemical properties, making it essential to understand these risks thoroughly in order to manage them effectively. The primary concerns surrounding CPAN include its explosive potential, health hazards associated with exposure, and its environmental impact.

Explosion Risk

One of the most significant safety risks associated with ammonium nitrate is its potential to cause explosions. As a potent oxidizer, ammonium nitrate can fuel the combustion of other materials, particularly in environments where it comes into contact with heat or contaminants. When heated to temperatures exceeding 180°C (356°F), ammonium nitrate begins to decompose. This decomposition process releases a mix of gases, including nitrous oxide, ammonia, and water vapor, which can rapidly increase pressure in confined spaces. If these conditions are combined with additional heat or contaminants, the situation can escalate into an explosion.

The risks associated with ammonium nitrate were tragically underscored in the 2020 Beirut port explosion, where over 2,700 tons of improperly stored ammonium nitrate ignited. The resulting explosion was one of the largest non-nuclear blasts in history, causing widespread destruction, killing over 200 people, and leaving thousands injured. This catastrophic event highlights the importance of proper storage, handling, and safety protocols when dealing with large quantities of ammonium nitrate.

To minimize explosion risk, it is crucial to store ammonium nitrate in cool, dry environments, away from combustible materials, and to follow stringent regulations governing its transportation and storage. In many countries, ammonium nitrate is classified as a hazardous material, subject to strict regulatory oversight. Facilities handling large quantities of ammonium nitrate must implement robust safety measures, including fire-resistant storage, adequate ventilation, and careful monitoring of environmental conditions to prevent accidental detonation.

Health Hazards

Beyond the risk of explosion, ammonium nitrate also poses significant health hazards to those handling or working near it. One of the primary concerns is the inhalation of ammonium nitrate dust. When ammonium nitrate is processed, transported, or stored, fine particles can become airborne, potentially exposing workers to inhalation risks. Short-term exposure to ammonium nitrate dust can cause irritation of the respiratory tract, leading to coughing, throat irritation, and shortness of breath. Prolonged or repeated exposure, especially in poorly ventilated environments, can lead to more serious respiratory conditions, including chronic bronchitis and other pulmonary issues.

The National Institute for Occupational Safety and Health (NIOSH) has established guidelines for permissible exposure limits (PEL) to minimize these risks. NIOSH recommends that the concentration of ammonium nitrate dust in the air should not exceed 5 mg/m³ over an 8-hour workday. In environments where ammonium nitrate dust is a concern, it is critical to use personal protective equipment (PPE) such as respirators and to ensure proper ventilation to reduce the concentration of airborne particles.

In addition to respiratory hazards, ammonium nitrate can cause irritation upon contact with skin or eyes. Prolonged skin exposure can lead to dermatitis, while eye contact may cause significant irritation, redness, and discomfort. Workers handling ammonium nitrate should wear appropriate protective clothing, including gloves and eye protection, to minimize the risk of direct contact. In case of exposure, immediate flushing of the skin or eyes with water is recommended to prevent further irritation or injury.

Ingestion of ammonium nitrate, though less common in industrial settings, can also pose serious health risks. Ingesting significant amounts of ammonium nitrate can lead to symptoms such as abdominal pain, nausea, vomiting, and in severe cases, methemoglobinemia, a condition in which the blood's ability to carry oxygen is reduced, leading to cyanosis (bluish skin) and respiratory distress. In such cases, immediate medical attention is necessary.

Environmental Impact

While the primary focus of ammonium nitrate hazards is often on human health and safety, its environmental impact should not be overlooked. One of the key environmental concerns associated with ammonium nitrate is its potential to cause eutrophication when it enters waterways. Ammonium nitrate is highly soluble in water, and when it is improperly stored, transported, or applied in agricultural settings, it can be washed into nearby streams, rivers, and lakes through runoff.

Eutrophication occurs when excessive nutrients, such as nitrogen from ammonium nitrate, enter aquatic ecosystems, stimulating the rapid growth of algae. While algae are a natural part of aquatic ecosystems, their overgrowth can have harmful effects. As algae die and decompose, they consume large amounts of oxygen, leading to oxygen depletion in the water. This process, known as hypoxia, can create "dead zones" where oxygen levels are too low to support most forms of aquatic life. Fish, crustaceans, and other marine organisms may suffocate and die, leading to severe ecological imbalances.

The agricultural use of ammonium nitrate as a fertilizer is one of the main contributors to nutrient runoff and eutrophication. To mitigate these environmental impacts, it is essential to apply ammonium nitrate carefully and in accordance with best agricultural practices. This includes using precise amounts to avoid over-fertilization, implementing buffer zones to prevent runoff into waterways, and adopting practices such as cover cropping and reduced tillage to minimize soil erosion and nutrient loss.

Furthermore, regulatory measures such as the Clean Water Act in the United States and similar environmental protection laws in other countries have been established to limit the release of ammonium nitrate and other pollutants into waterways. Proper containment, storage, and handling practices can also prevent accidental spills or leaks that could contribute to environmental contamination.

Chemical Pure Ammonium Nitrate (CPAN) plays a critical role in industries such as agriculture, mining, and explosives manufacturing, but it presents a range of safety risks and hazards that must be carefully managed. Its potential for explosion, health hazards from inhalation and contact, and environmental impact through eutrophication all underscore the importance of stringent safety protocols. Proper handling, storage, and regulatory compliance are essential to minimizing these risks and ensuring the safe use of ammonium nitrate in industrial and agricultural applications. Through these efforts, industries can harness the benefits of CPAN while minimizing its dangers to people and the environment.

Handling and Storage Guidelines

Given the hazardous nature of Chemical Pure Ammonium Nitrate (CPAN), particularly its explosive potential and health risks, strict handling and storage guidelines are essential to ensure safety. Improper storage and handling can lead to catastrophic incidents, as demonstrated in several high-profile industrial accidents. By adhering to proper guidelines, industries can minimize the risks associated with CPAN while ensuring safe operations.

Storage Conditions

CPAN must be stored in carefully controlled conditions to prevent decomposition, contamination, or accidental detonation. The key to safe storage is maintaining a cool, dry environment. Temperatures exceeding 30°C (86°F) can accelerate the decomposition of ammonium nitrate, which could result in the release of gases and increase the likelihood of an explosion. Therefore, the storage facility should be temperature-regulated, ensuring that CPAN is kept well below its decomposition temperature threshold of 180°C (356°F).

In addition to temperature control, CPAN should be stored away from heat sources and flammable materials. It acts as an oxidizer, meaning it can intensify fires if it comes into contact with flammable substances. To avoid the buildup of gases that might pose an explosion risk, storage areas should be well-ventilated. Ventilation prevents any gases released during minor decomposition from accumulating and creating hazardous conditions.

Another important factor is moisture control. Although CPAN is highly soluble in water, exposure to moisture can lead to clumping and uneven distribution during use. Proper storage should prevent exposure to humidity by sealing CPAN in moisture-proof containers and using desiccants if necessary.

Containment

The containers used to store CPAN must be non-reactive to avoid chemical reactions that could compromise the stability of the ammonium nitrate. Materials such as polyethylene or polypropylene are ideal for containing CPAN because they do not react with the compound. Metal containers should generally be avoided as they can corrode over time, and the corrosion products may trigger unwanted reactions with ammonium nitrate.

For bulk storage, special containment systems should be in place to prevent leaks and ensure early detection of any issues. Facilities storing large quantities of CPAN should be equipped with leak detection systems, which can alert personnel to any potential spills or degradation of containment. Furthermore, secondary containment measures such as containment dikes or spill trays should be implemented to minimize the risk of contamination in the event of a leak or spill.

CPAN should also be kept isolated from incompatible materials, including reducing agents, acids, fuels, and other flammable or reactive chemicals. Keeping these materials separate will reduce the risk of chemical reactions that could lead to explosions or fires.

Handling Procedures

Personnel responsible for handling CPAN must follow rigorous safety protocols to minimize exposure and prevent accidents. The use of Personal Protective Equipment (PPE) is critical. Workers should wear protective gloves, goggles, and respiratory protection to guard against direct contact with the material or inhalation of its dust, which can cause respiratory irritation.

Work areas where CPAN is handled should be well-ventilated to prevent the buildup of ammonium nitrate dust or gases, which could lead to health risks or explosions. Dust is a particularly hazardous form of CPAN, as it can become airborne and increase the risk of inhalation. Therefore, dusty conditions should be minimized, and dust suppression measures such as vacuum systems or dust collectors should be implemented.

It is also important to avoid handling CPAN in areas where incompatible substances are present. Contact with reducing agents, acids, or combustible materials can lead to dangerous chemical reactions. Personnel should ensure that CPAN remains in a controlled environment, away from potential contaminants, and that any tools or equipment used in its handling are clean and free from substances that could react with the chemical.

Additionally, facilities should establish emergency protocols for handling incidents involving CPAN, such as accidental spills or fires. These protocols should include procedures for safely containing the material, evacuating personnel, and notifying emergency responders.

The safe handling and storage of CPAN require careful adherence to specific guidelines to prevent accidents. By maintaining appropriate storage conditions, using non-reactive containment systems, and following stringent handling procedures, the risks associated with CPAN can be significantly reduced. Regular training for personnel and routine safety checks are essential components of a robust safety management system, ensuring that the compound is managed in the safest possible manner.

Case Study: 2020 Beirut Explosion

The Beirut port explosion on August 4, 2020, is one of the most significant examples of the hazards associated with ammonium nitrate. Approximately 2,750 tonnes of ammonium nitrate, which had been improperly stored in a warehouse, exploded, resulting in over 200 deaths, thousands of injuries, and widespread damage. The incident underscores the critical importance of proper storage and handling protocols for CPAN.

Regulatory Guidelines

OSHA Standards: The Occupational Safety and Health Administration (OSHA) provides regulations for the safe handling and storage of ammonium nitrate. These regulations include guidelines for safe storage practices, emergency response procedures, and regular safety training for personnel.

NFPA Guidelines: The National Fire Protection Association (NFPA) classifies ammonium nitrate as a hazardous material and provides guidelines for its safe handling. According to NFPA standards, ammonium nitrate should be stored in a manner that minimizes the risk of fire and explosion.

Conclusion

Chemical Pure Ammonium Nitrate (CPAN) is a valuable chemical with diverse applications, but its potent nature necessitates strict adherence to safety and handling protocols. By understanding the risks, implementing proper storage and handling procedures, and adhering to regulatory guidelines, the potential hazards associated with CPAN can be effectively managed. The Beirut explosion serves as a stark reminder of the consequences of inadequate safety measures, reinforcing the need for vigilance and compliance in the management of this critical chemical.

References

National Institute for Occupational Safety and Health (NIOSH). (2021). "Ammonium Nitrate."

Occupational Safety and Health Administration (OSHA). (2020). "Safety and Health Regulations for the Handling of Ammonium Nitrate."

National Fire Protection Association (NFPA). (2019). "NFPA 400: Hazardous Materials Code."