.jpg)

As a strong oxidizing agent, ammonium nitrate makes an explosive mixture when combined with a fuel such as a hydrocarbon, usually diesel fuel (oil) or, sometimes, kerosene. Because ammonium nitrate and fuel oil (ANFO) are readily available in bulk, ANFO mixtures have occasionally been used for improvised bombs—for example by the Provisional IRA and in the Oklahoma City bombing.

Ammonium nitrate is used in military explosives such as the daisy cutter bomb, and as a component of amatol. Military mixtures are often spiked with about 20 percent aluminum powder as well, increasing the blast power, but with some loss of brisance. One example of this is Ammonal, which contains ammonium nitrate, TNT & aluminum. Aluminized mixtures are very effective under confinement, as in underwater demolition, torpedoes, and rock blasting. Very cheap water-based blasting slurries tap the power of an aluminum-water reaction with enough ammonium nitrate added to burn off the resulting hydrogen.

Ammonium nitrate is also an explosive in its purest form although it is an unusually insensitive one. Explosive properties become much more evident at elevated temperatures. When ammonium nitrate is fused and "boiled" to generate nitrous oxide, it has been claimed to be as sensitive as dynamite at about the 240 °C operating temperature.

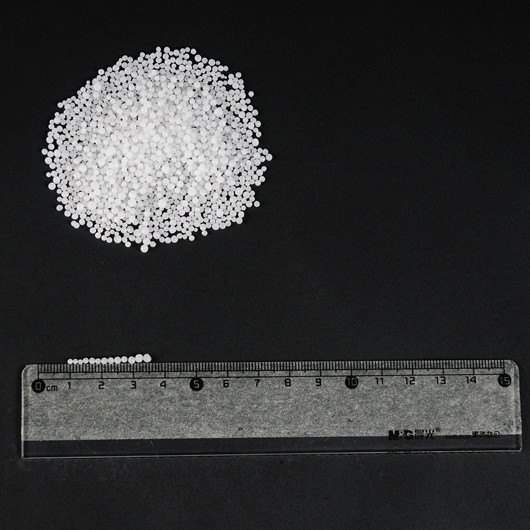

This exothermic reaction can run away and reach detonation velocities (without proper temperature controls). The extent of this possibility has been demonstrated several times, most notably at the Ohio Chemical plant in Montreal in 1966. Millions of pounds of relatively pure ammonium nitrate have been (accidentally) detonated when subjected to severe heat and/or shocks (see "Disasters" below). Ammonium nitrate has also found use as a solid rocket propellant, but for a while ammonium perchlorate was frequently considered preferable due to higher performance and faster burn rates. Lately, favor has been swinging back towards ammonium nitrate in rocketry, as it delivers almost as much thrust without producing an exhaust jet full of gaseous hydrochloric acid (HCl) and without the extra expense and sensitivity hazards. Fertilizer-grade ammonium nitrate (FGAN) is manufactured in more compact form, with much lower porosity, in order to achieve greater stability and lower sensitivity to detonation, whereas technical grade ammonium nitrate (TGAN) prills are made to be porous for better absorption of fuel and higher reactivity.